MM II – Machine Elements and Mechatronics II

| Lecturer | Type and scope of the lecture |

| Prof. Dr.-Ing. Eckhard Kirchner | 8 hours a week (lecture + exercise) |

| Lecture | Exercise |

|

Lecture in summer semester Tu 09:50 – 11:30 in L402/1+2 Fr 08:00 – 09:40 in L402/1+2 |

distribution for the exercise groups is announced the first lectures |

| Language of lecture and exam is German. | |

| Contact | |

| For organisational questions regarding the lecture, lecture hall and group exercise or examination in MM II, please contact only: mm2@pmd.tu-… | |

Information about the oral supplementary examination MM II

The oral supplementary examination lasts approximately 75 minutes (including the announcement of grades) and consists of two parts, a written part and an oral part:

- In the written part (duration: 30 minutes), candidates are required to constructively solve a drive technology problem and present their solution as a hand-drawn sketch on A4 paper. The scope of the task is approximately 30% of a typical design task from an exam. No aids other than drawing tools are permitted.

- In the oral part (duration: approx. 45 minutes), the constructive solution from the written part and any errors are first discussed and analysed. This is followed by an examination of your basic understanding of the subject ‘Machine Elements and Mechatronics II’, with the entire content of the course being relevant to the examination. However, the focus is on the essential interrelationships and the basic approach to the design of machine elements and the fundamental calculation equations required for this – simply reciting equations is not necessary! Furthermore, you are expected to know and be able to interpret relevant influencing factors and parameters. A script including errata and all lecture slides will be provided on site.

We wish you much success in your preparation.

News

News can be found at the institute's news.

Contents

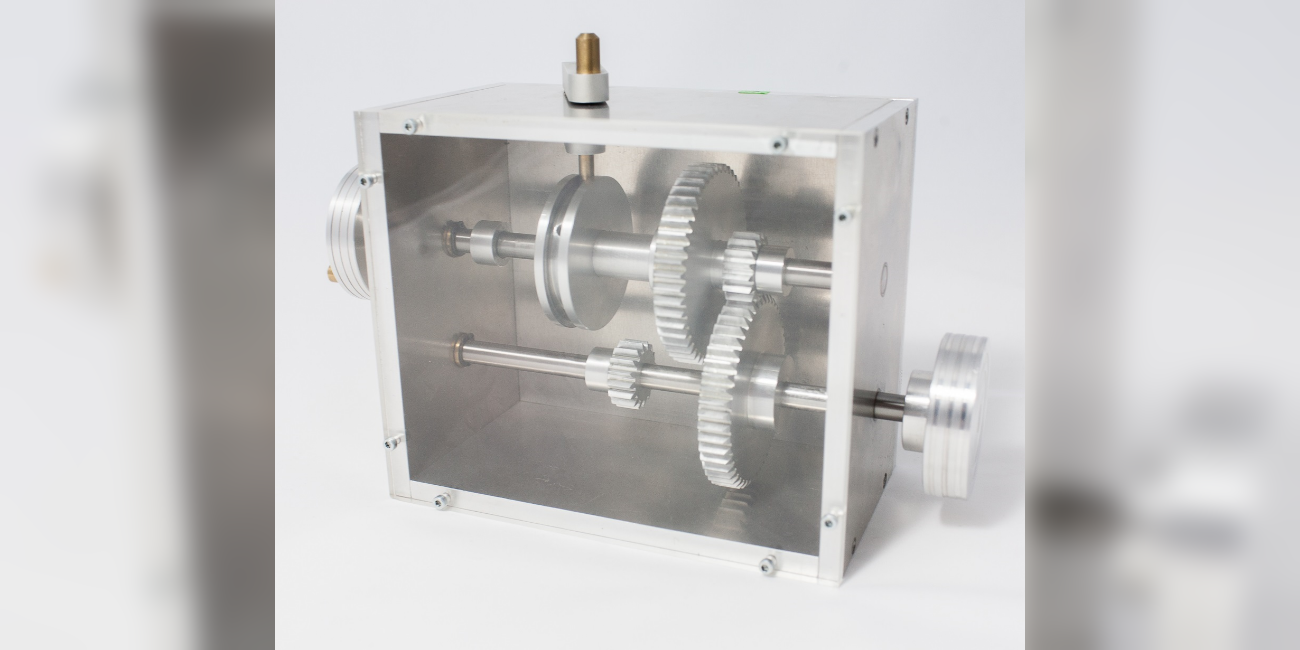

The second part of the lecture “Machine Elements and Mechatronics” deals with the mechanical machine elements. It starts with the design methods for components in general and their dimensioning under stationary and unsteady use. After that, specific mechanical machine elements are looked at, starting with simple elements. Based on connections, students deal with suspensions, dampers, couplings, bearings and keyways as well as seals.

Moodle

Information, lecture notes and supplementary materials are available on the e-learning platform Moodle (Moodle_TU_Darmstadt) of the course “Machine elements II”.

Additional documents and links

The collection of links is only available for members of the TU Darmstadt. Login with your TU-ID to get access.

Contact Persons

Prof. Dr.-Ing. Eckhard Kirchner

Contact

kirchner@pmd.tu-...

work +49 6151 16-21171

Work

L1|01 251

Otto-Berndt-Straße 2

64287

Darmstadt

Patrick Kortenbusch M.Sc.

Working area(s)

Contact

patrick.kortenbusch@tu-...

work +49 6151 16-21180

Work

L1|01 242

Otto-Berndt-Straße 2

64287

Darmstadt