AutoBeam

Enabling Additive Manufacturing through Process Adaptation and Beam Shaping for Lightweight Automotive Structures

Background

The increasing demands for sustainability, energy efficiency and resource conservation in the mobility sector are presenting the automotive industry with major challenges. Lightweight construction strategies are gaining importance in this context, as they make a significant contribution to reducing vehicle mass and thus energy consumption. Additive manufacturing (AM) is considered a key technology for efficiently producing functionally integrated and load-optimized components with complex geometries. In particular, laser powder bed fusion (PBF-LB/M) opens up new design possibilities for lightweight automotive construction. However, in industrial practice, the use of this technology remains limited to niche applications. The reasons for this lie in the low productivity of the manufacturing processes, the resulting high part costs, and limited process understanding, especially regarding the processing of aluminum alloys. Furthermore, there is a lack of established methods for the systematic identification, evaluation and design of components suitable for additive manufacturing. Consequently, the economic use of additive technologies for structurally relevant components in automotive series production has so far hardly been realized.

Objectives

The AutoBeam research project aims to significantly advance additive manufacturing by integrating novel, dynamically controllable laser beam sources with variable beam shaping. The ability to flexibly adapt the laser beam profile to the specific requirements of a component is intended to enable the reliable and efficient production of both delicate and massive part features. The project focuses on processing aluminum alloys, which play a central role in lightweight automotive applications. The targeted increase in volumetric build rate from approximately 100 cm³ per hour to at least 250 cm³ per hour is expected to greatly improve the economic viability of the technology and make additive manufacturing attractive for small-series applications in the automotive sector. This technological goal is complemented by the development of methodological and digital tools to systematically identify suitable components, evaluate them in terms of manufacturability, cost-effectiveness, and sustainability, and design them accordingly. In addition to technical aspects, ecological assessment is also a central concern, especially with regard to the carbon footprint across the entire process chain. Transferring the generated knowledge into industrial application is an integral part of the project.

Approach

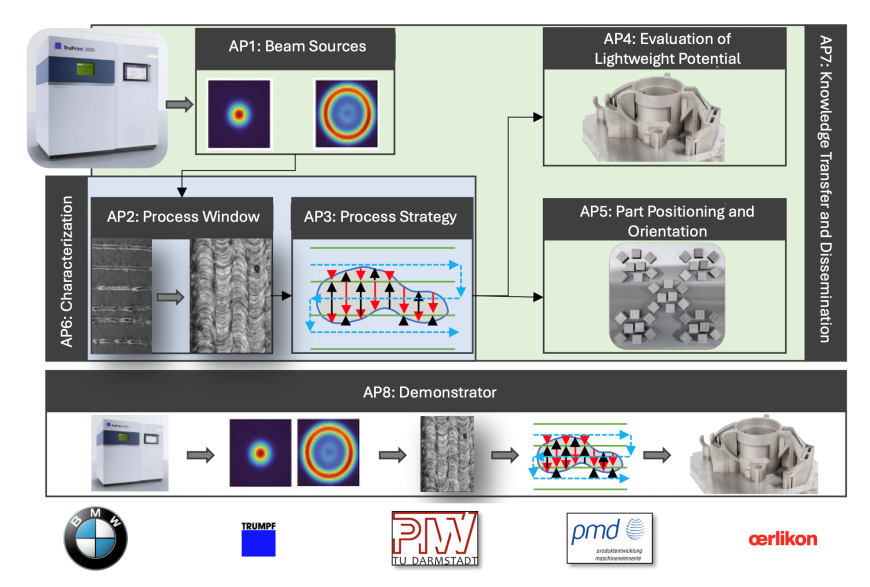

Within the project, two novel laser beam sources will first be integrated into an industrial PBF-LB/M system. These sources allow for flexible adjustment of the beam profile and energy input to meet different geometric and material requirements. In parallel, a comprehensive process-oriented evaluation of the beam sources will be carried out, alongside a detailed investigation of their interactions with various aluminum powders, including sustainably produced variants. Based on this, the Institute for Production Management, Technology and Machine Tools (PTW) at TU Darmstadt will develop data-driven models for process configuration and the generation of part-specific scan strategies. These will be supported by a geometry analysis tool that evaluates the component layer by layer and derives optimized process paths. The goal is to enable automated adaptation of process parameters to local requirements within a component. In addition, the Institute for Product Development and Machine Elements will develop a methodological approach for identifying and evaluating suitable components. A model will be created that links geometric, technological, economic, and ecological criteria. The resulting data will be organized in a database, analyzed, and visualized via a graphical user interface. This enables the identification, evaluation and design of promising candidates for additive manufacturing. The developed methods will be validated throughout the project using a demonstrator component produced with the new technologies under near-industrial conditions. To assess mechanical properties, both destructive and non-destructive material testing will be conducted. The results will feed back into further development of the process strategies and design models. To ensure successful knowledge transfer, training sessions, workshops and digital dissemination measures will be implemented, enabling targeted application of the project results in industrial settings. The close integration of technological development, methodological advancement and industrial validation creates a comprehensive framework that empowers additive manufacturing for lightweight automotive construction and lays the foundation for economically viable series production.