MiMoSe II

Microelectronic modular system for sensor-integrating machine elements

Initial situation

The integration of sensor technology transforms conventional machine elements into cyber-physical systems, known as sensor-integrated machine elements (SiME).

Priority Program 2305 focuses on the direct integration of sensor systems into the existing mechanical structure of conventional machine elements, such as screws, gears, and keyways. The systematic development of SiME, particularly considering severely limited installation space, efficient data management, and self-sufficient energy management, represents a major challenge. The necessary interdisciplinary collaboration between the fields of mechanics, (micro)electronics, and software requires an early, coordinated approach to bring together the respective development domains.

After models for the modular development of SiME were developed and implemented as part of the predecessor project “MiMoSe,” the task now is to resolve open research questions and supplement the functionality of the modular system with energy self-sufficiency, wireless communication, and update capability, as well as support for test procedure selection. Consequently, the aim of the project is to methodically support the interdisciplinary, systematic development of SiME and to research it using the example of fastening and motion bolts. The expertise required for development is provided by the project partners PKT (TU Hamburg) – methodical product development, MST (TU Hamburg) microelectronics, and pmd (TU Darmstadt) – machine elements.

Project objectives

The overall objective of the project is to expand the microelectronic modular system for sensor systems in SiME, which was developed in the previous project, to include self-sufficient functions and testing.

Using the example of sensor-integrated fastening and motion bolts, the model-based modular system will be tested and the functionality of the configured sensor systems will be verified. In addition, the necessary methods for the configuration and preliminary design of SiME are to be developed. With the integration of sensor systems into standardized machine elements, a wide variety of process-relevant measurement tasks can be performed by collecting and evaluating data in situ and transmitting it to the higher-level system. Using the bolt as an example of a machine element, this project aims to use the modular system to be developed to generate suitable sensor systems based on different strategies, implement them in prototypes, integrate them, and finally test them experimentally.

Approach

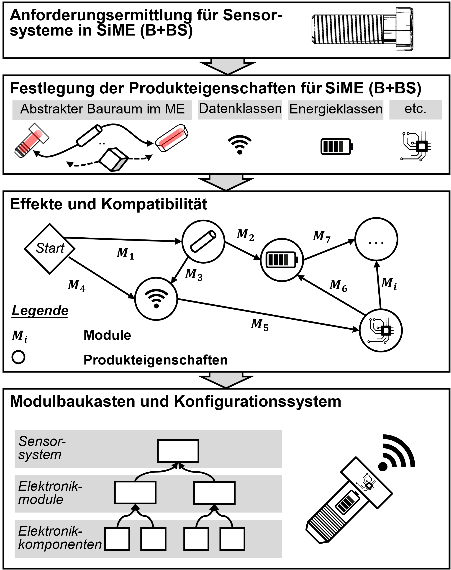

First, as shown in Figure 2, requirements for the energy modules and wireless communication in SiME are determined based on motion and fastening bolts. Based on the determined requirements, the necessary product characteristics are then defined. Additionally relevant test procedures and test cases are determined.

It is investigated whether a methodological link between specific requirements and test procedures is possible and how this can be incorporated into the modular system. Subsequently, the required modules for the respective subfunctions are determined, their compatibility with each other is analyzed, and their interaction with the already evaluated prototype and its functional integrity on the integrated machine element is investigated. Finally, the extended modular system is tested using fastening and motion bolts. For this purpose, demonstrators and a suitable physical test environment are developed for their experimental investigation. The focus here is on static and harmonically dynamic tests and the recording of the relevant mechanical variables. The functional verification of the developed SiME and the modular system is carried out by comparing the measured data with the predicted data.