TecCond

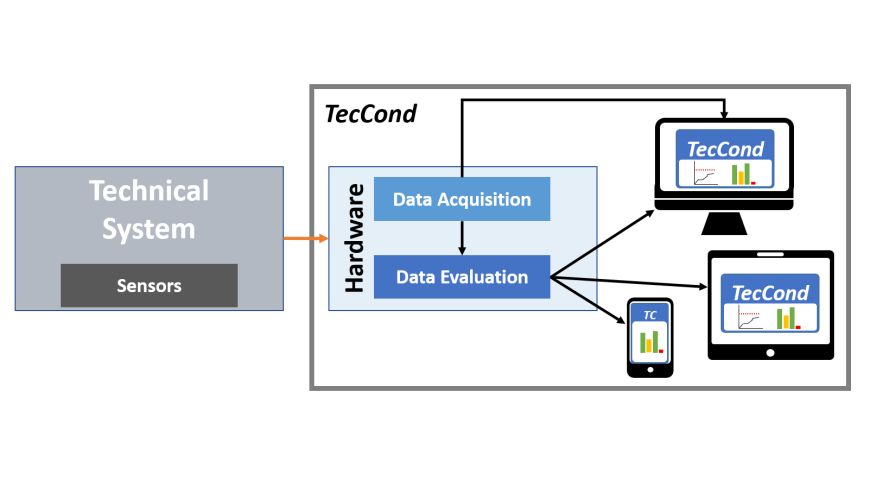

Technology Condition Monitoring: System for monitoring the real-time condition of technical systems

Initial situation

In the course of a product development, many calculation models are often set up, which are used for dimensioning the technical system and for determining maintenance intervals and maintenance measures. The models range from simple target/actual comparisons to measurement data from tests and highly complex simulations. This causes the following difficulties:

- Large number of models leads to confusion

- Small changes in boundary conditions (e.g. dimensions, weight, loads) cause a large amount of calculation work (costs)

- There are often dependencies between the individual models

- Experience from previous product generations must also be taken into account

In addition to the general complexity during the product development process, the more diverse the possible applications of the product, the more often “unpredictable” operating conditions prevail in real operation (different loads, routes, speeds, driving cycles, etc.), which can only be roughly estimated during design. This results in the following problems for the design and later operation:

- The dimensioning of the system is only suitable for selected cases.

- The maintenance intervals are mostly wrong, which causes unnecessary costs.

The InTraProd transport system is a concrete example of a technical product that can be exposed to many different operating conditions due to a large number of possible events. Once multiple travel paths are linked, it is no longer possible to predict which shuttle will transport which product to which plant, as these decisions are made by an intelligent control system. In this project, the transport system serves as an example product to answer specific questions.

Project goals

The TecCond project is developing an approach to end-to-end digitization across the entire product lifecycle of technical systems, using the example of an autonomous transport system from development through production to maintenance. TecCond represents an evolutionary stage of condition monitoring, since not only simple information is collected, but knowledge is generated from the existing data. Mechanical components are fundamentally stressed, which causes components to fatigue continuously. The operating behavior itself, however, does not change. However, conventional approaches do not react until the “first failures” occur. TecCond, however, has a model-based approach with which it will be possible to make statements about an overall system without changes occurring within the data.