Additive Manufacturing

The additive manufacturing of products is becoming an important competitive factor in the context of the increasing digitalization of manufacturing, the rising cost pressure, the advantage of tool-free manufacturing, the exceptional geometric design freedoms as well as through an increasing demand for customer individualization. The resulting potential for the design of additively manufactured products has not yet been systematically exploited, particularly in the search for solutions.

Additive manufacturing processes require digital 3D design data to manufacture products. In a subsequent step, these are prepared for the additive manufacturing process and transferred to the machine. In contrast to conventional processes, the final geometry is not achieved by removing material, but by applying material layer by layer. Originally, additive manufacturing was used to produce prototypes (rapid prototyping), but today the properties of additively manufactured products are sufficient to also produce tools (rapid tooling) and finished products (rapid manufacturing). Additive manufacturing processes thus have the potential to reduce the manufacturing time and cost of a component while ensuring a high degree of customizability. However, the design of additively manufactured components requires a mindset of the developer that is adapted compared to classical design theory in order to utilize the specific potentials of the manufacturing process compared to conventional processes.

Goal

A central goal of the research unit is the development of methodical support for the developer, tailored to project-specific requirements, in order to be able to better utilize the potential of additive manufacturing already in the concept phase of product development. The aim is to enable the developer to think in additive terms, i.e. to make full use of the advantages offered by the process, thereby offsetting the higher manufacturing costs of the process against a significantly higher functional added value of the products. Furthermore, new potentials of additive manufacturing will be developed at the work area, which will expand the technically feasible field of application of this technology. Methodical approaches will also be used to provide developers with tools for reducing manufacturing costs.

Research approach

In the research approach, the development of design instructions and guidelines as well as principle partial solutions as mental suggestions for existing development and design tasks is envisioned.

In addition, the limitations of additive manufacturing processes are analyzed in order to overcome them through the targeted design of components. For example, in contrast to general efforts towards integral design, components are separated in order to reduce support structures, increase the utilization of the build space or improve the surface quality by producing parts of the component using other machining production processes.

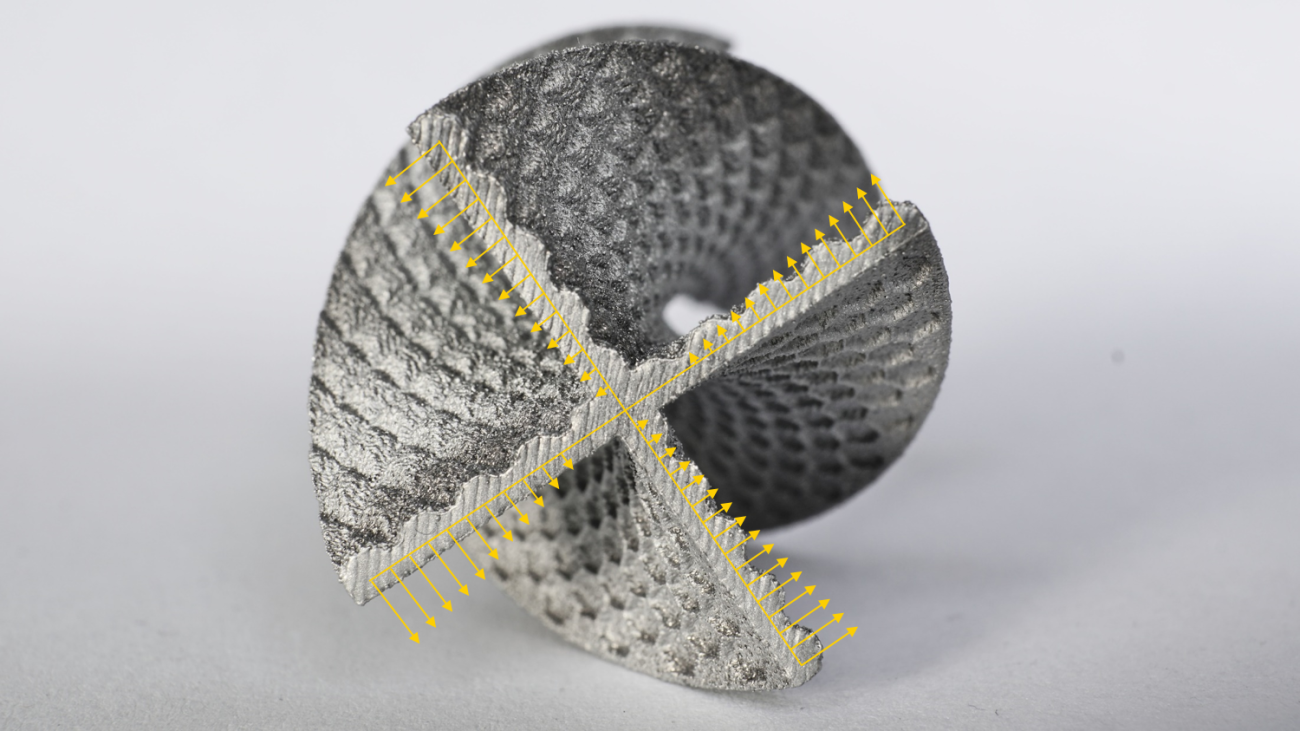

Grading of the microstructure of the material and the mesostructure of the components are also being investigated to optimize the lightweight design potential, with the aim of improving force conduction by selectively adjusting the stiffness of the microstructure.

Another approach is the development of prototypical additive manufacturing processes in order to identify process-related advantages and to be able to use them in the context of design notes.

Research projects

- Conversion and extension of FFF printers for the integration of continuous filaments

- Design and manufacture of components with graded properties as well as lattice structures by means of laser powder bed fusion

- Design methodology for targeted component joining and partitioning

- Development of new/adaptation of existing component connections for additive manufacturing

Teaching

The topic of design for additive manufacturing is part of various pmd courses. A basic introduction takes place in the context of “Machine Elements and Mechatronics II”. The topic is covered in more detail in the lecture series “Introduction to 3D Printing and Additive Manufacturing”. The potentials of additive manufacturing and how they can be exploited are taught in the chapter “Rapid Manufacturing” of the course “Smart Products, Services and Engineering” (SPES).

To practically test the taught content, a Makerspace was set up at pmd consisting of 8 filament printers (Prusa i3 MK3S+), a resin printer (Formlabs Form 3+) and a laser cutter (Trotec RayJet 50). In the project phase of SPES, students use the processes in the sense of rapid manufacturing to quickly develop and produce a functional product. Furthermore, in cooperation with the departments of civil engineering, electrical engineering and economics, the tutorial “Design for Additive Manufacturing” is offered to the students of these departments. There, the students use the potentials of additive manufacturing to solve various problems from the aforementioned disciplines within the framework of a development task.

Industry

We strive for intensive cooperation with partners from industry in order to apply and improve our research results in industrial development and research projects. Feel free to contact us!